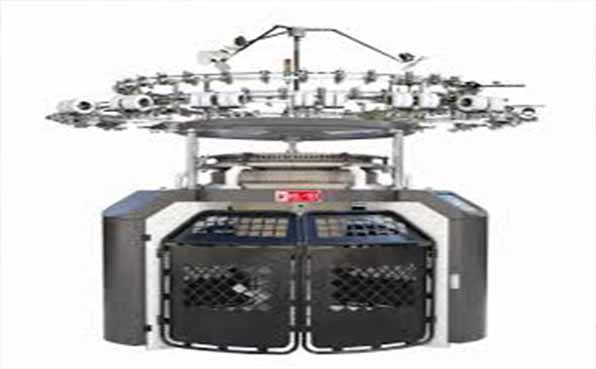

IMPORTED KNITTING MACHINES

Our company is well equipped with the latest up to date machinery which are capable of producing an innumerable high quality fabrics which are designed for production of knitted fabrics in Intarsia, Lighter heavy, Jerseys, Interlock, Jacquard, Loop Knit, Rib auto strips and many more types of knits in different dia, gauges & weights.